Once again in focus: set-up costs. Everyone knows that set-up costs should be kept as low as possible. Often there are many small adjustments that have to be made in the process in order to reduce costs significantly.

With a conventional injector you have to connect 3 air hoses, with ejector injectors often even 4. If there are 10 injectors on one mould, that makes 30 to 40 hoses. If only one pair is inverted, the injector will malfunction and in the worst case the mould may be damaged. To prevent this, differently coloured air hoses are suitable. These can be easily identified from each other, but in case of doubt they can still be connected incorrectly.

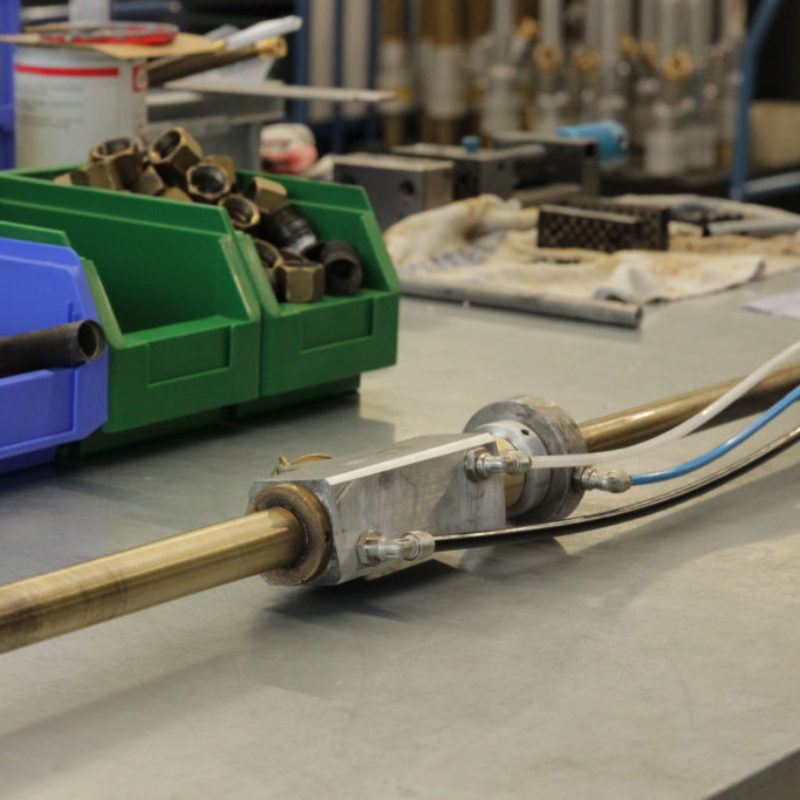

From now on we offer distinctive couplings, which are colour-coded and, in addition, cannot be confused with each other due to a special profile. The advantage is obvious. With these couplings you completely exclude any mix-ups. The employee cannot help but mount the couplings on the correct plugs.

An advantage that first customers have recognised. Distinctive nipples were retrofitted during basic maintenance. The cost of this amounted to about 15% of the total maintenance costs. We have compiled the currently available articles for you here